Electronics

Hot air rework station

The Hakko FR-810B hot air gun is used for de-soldering and rework applications in electronics, as well as to reduce heat shrink tubing.

- Temperature range: 50-600 °C

- Air flow: 5-115 L/min

Manufacturer: Hakko

Required training: General Maker Training, Introduction to Electronics and Soldering

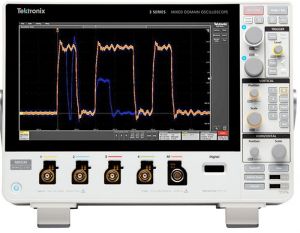

Oscilloscope

The Tektronix MD034 oscilloscope can be used to visualise signals within your prototype’s circuits and allows for quantitative measurements of a variety of circuit characteristics. It also features a spectrum analyser for analysis of the frequency characteristics of signals in your circuit.

- Spectrum analyser frequency range: 9 kHz-1 GHz

- Number of analogue channels: 4

- Sample rate: 2.5 GS/s

- Bandwidth: 200 MHz

Manufacturer: Tektronix

Required training: General Maker Training, Introduction to Electronics and Soldering

Power supply

Power electronic devices with this adjustable triple output DC power supply. Supporting either constant-voltage or constant-current output on channels 1 and 2, as well as a fixed 5V output on channel 3, you can also protect your circuits with the current limiting function.

- Voltage output (channels 1 and 2): 0-30 V or 0-60 V in series

- Current output (channels 1 and 2): 0-3 A or 0-60 A in parallel

- Voltage output (channel 3): 5 V fixed

- Current output (channel 3): 3 A maximum

Manufacturer: GW Instek

Required training: General Maker Training, Introduction to Electronics and Soldering

Signal generator

The Tektronix AFG1022 Function Generator can be used to generate a variety of waveforms from its two outputs, including sine, square, ramps, pulses or noise for your circuits. It can be used to test amplifiers, create clock signals or as a variable voltage input to a circuit.

- Output frequencies (sine): 1 µHz-25 MHz

- Output frequencies (square): 1 µHz-12.5 MHz

- Output resolution: 14 bit, 125 MS/s with 8000 points record length

- Amplitude: 1 mVp-p-10 Vp-p into 50 Ω loads

Manufacturer: Tektronix

Required training: General Maker Training, Introduction to Electronics and Soldering

Soldering iron

The Pace MBT350 solder, desolder and rework station allows for the soldering, desoldering and rework of through-hole and surface mount components for prototyping or repair. A variety of tips are available to accommodate a wide variety of projects.

- Temperature stability: ± 1.1 oC

- Temperature range: 37-482 oC

- Vacuum rise time: 150 ms average

- Maximum vacuum: 10 psi

- Maximum pressure: 18 psi

- Maximum air flow: 8 SLPM

Manufacturer: Pace

Required training: General Maker Training, Introduction to Electronics and Soldering

Digital microscope

Inspect your circuits in high definition with a 50x zoom digital microscope camera. You can check for hairline shorts or just admire your soldering prowess up close.

- Magnification levels: 1.3x-53x

- Frame rates: 60, 50, 30 or 25 fps

- Resolution: 1920 x 1080p

- Field of view: 1.6-409mm

Manufacturer: Tagarno

Required training: General Maker Training, Introduction to Electronics and Soldering

PCB stencil printer

This LPKF ProtoPrint S4 stencil printer is used to quickly and accurately apply soldering paste across all the pads on a printed circuit board (PCB) to ready it for component placement and then reflow soldering.

Manufacturer: LPKF

Required training: General Maker Training, Introduction to Electronics and Soldering

Pick and place

The Autotronik BA385 is a robotic machine you can use for high-precision placing of electronic components like capacitors, resistors and integrated circuits onto PCBs.

- Placement rate: 3400 components per hour

- Feeder capacity (8 mm): up to 128 tape feeder

- Component size: 0.6 x 0.3 mm to 150 x 100 mm

- Resolution

- X/Y axis: 5 µm

- Z axis: 10 µm

- Rotation: 0.9o per step

- Placement accuracy: ± 0.01 mm

- Repeatability: ± 0.01 mm

Manufacturer: Autotronik

Required training: General Maker Training, Introduction to Electronics and Soldering

Reflow oven

Use this LPKF convection reflow oven for reflow soldering an entire printed circuit board. You can customise the oven for different heating profiles and process logs.

- Maximum preheat temperature: 220 oC, time: 999 s

- Maximum reflow temperature: 320 oC, time: 600 s

- Maximum reflow temperature: 220 oC, time: 64 h

- Temperature stabilisation time: < 5 min

Manufacturer: LPKF

Required training: General Maker Training, Introduction to Electronics and Soldering