Services for Industry

MCFP offers consultation and fee-for-service solutions to industry researchers. We can apply our broad capability and expertise to help answer your process related questions.

To discuss your analysis needs with our Specialists, please either submit an access request online, or email us directly, by following the links below.

Submit a Request Online Contact Us by Email

Materials characterisation

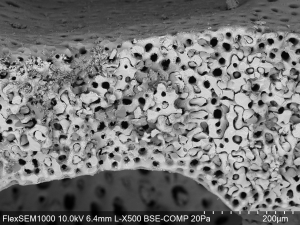

Scanning electron microscopy (SEM) enables the inspection of devices, components, materials, and surfaces. Our flexible SEM capability is applicable to the imaging of metals, ceramics, minerals, semiconductors, polymers, fibres, and particles. We can provide the inspection and measurement of component dimensions, the imaging of surface topography, microanalysis composition by SEM-EDX with an elemental range from boron (5) to californium (98), and the identification of unknown solids, defects, contaminants, and corrosion of solids. We can accept specimens up to 50 mm diameter and 40 mm thickness.

Phase identification

Our X-ray characterisation capability enables the analysis of solids and powders, providing semi-quantitative phase analysis of solids and powders by XRD, elemental and oxide composition by XRF, identification of unknown solids, matching of XRD patterns to ICDD-4+ 2021 Database, crystallinity and amorphous content. Ideally specimens should be in the form of a powder with the consistency of flour – dry, and ground to ~50 μm particle size and generally 2 g is required, but this can be as small as 20 mg, depending on the analysis. Specimen preparation as a service is also available. For solid samples the maximum size for standard data collection is 39 mm in diameter, 5 mm thickness and the sample surface must be flat.

Surface chemistry

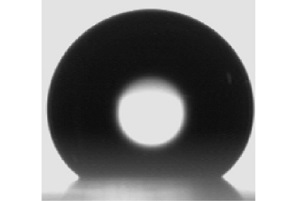

Optical imagery of drops placed on a solid surface enables the determination of surface and interfacial parameters. The contact angle of a drop on a surface informs the wetting behaviour of the solid with the liquid. We can provide optical measurements of static and dynamic contact angle, wetting of solid surfaces, surface free energy of solids, and surface and interfacial tension of liquids. Our instrument can accept a maximum specimen size of 220 x 220 (L x W) and 70 mm thickness.

Microscopy and Imaging

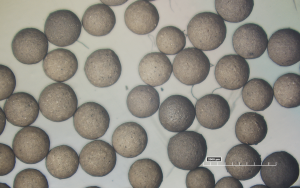

We have flexible methods for general purpose imaging of materials including general purpose optical microscopy, the inspection and measurement of component dimensions, the imaging of surface topography, optical 2D/3D microscopy with 3D surface profiles, and high resolution electron microscopy. Please contact us to discuss your needs and we can provide the most suitable imaging technique for your question.

Particle characterisation

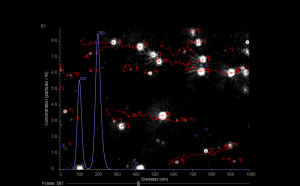

Two technologies that can be used to characterize nanoparticles are flow cytometry and nanoparticle tracking analysis. With flow cytometry, a suspension of nanoparticles is passed one-by-one in front of a laser. As they pass through the laser beam they scatter light, and this gives information on particle size and concentration. Nanoparticle tracking analysis also identifies particles with scattered laser light, but uses image analysis to track the movement of individual particles. The size of each particle can then be determined based on the characteristic way they move. We offer the analysis of particle size distribution and concentration for a size range of 10 - 2000 nm and concentration range 106 - 109 particles per mL.