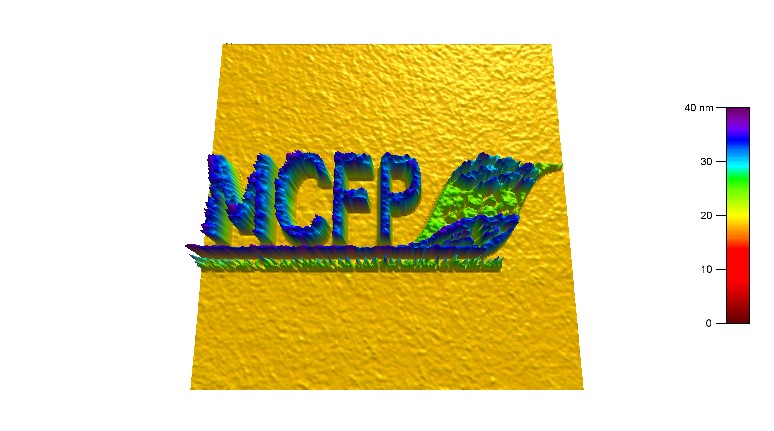

Materials Characterisation and Fabrication Platform

The Materials Characterisation and Fabrication Platform (MCFP) supports materials research through advanced instrumentation, analysis and characterisation. The MCFP welcomes all users across the scientific community, from universities and research institutes to industry.

-

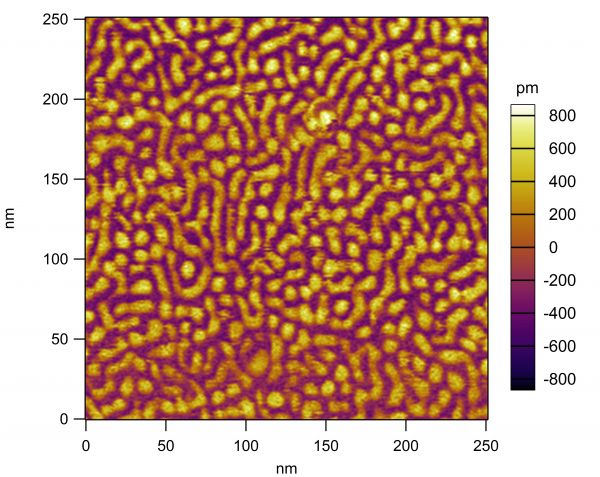

Nanomaterials Characterisation

Nano- and micro-scale characterisation of bulk and thin materials, nanoparticles, living cells and tissues

-

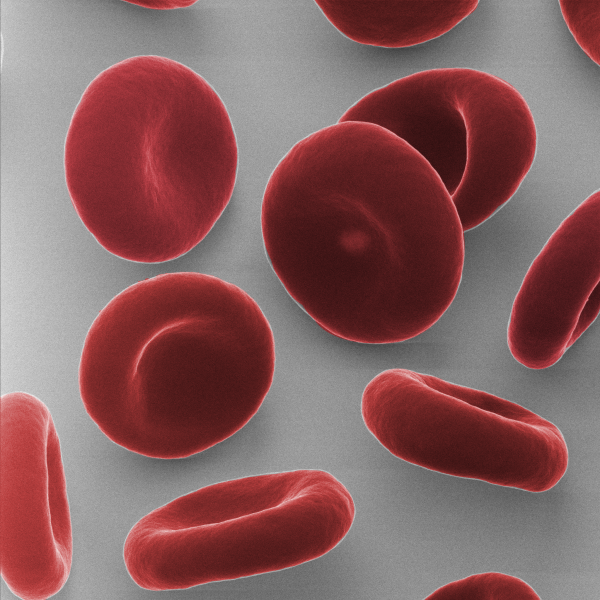

Cytometry and Particle Characterisation

Analysis of cells in suspension

-

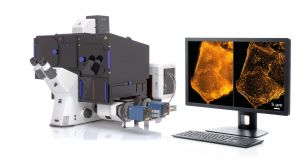

Advanced Fluorescence Imaging

Cutting-edge imaging technology of living or fixed samples

-

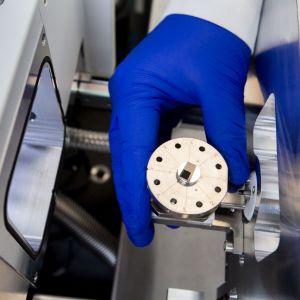

Electron and Ion Microscopy

High resolution surface imaging and nanoscale milling and patterning

-

X-Ray Characterisation

Investigate the crystalline nature of materials

-

Vibrational Spectroscopy

Confocal Raman and FTIR microspectroscopies

-

Nanofabrication

The MCFP Nanofabrication platform supports University of Melbourne (UoM) researchers accessing the Melbourne Centre for Nanofabrication (MCN) located in Clayton.

-

Services for Industry

DR ELENA TARAN

Platform Manager

Elena joined The University of Melbourne as MCFP Manager in 2019. Her previous appointments included positions with School of Chemical Engineering and Australian National Fabrication Facility at The University of Queensland. Elena completed her PhD in the Surface Control Engineering Laboratory of Kyoto University. She is an expert in surface characterisation by scanning probe microscopy, vibrational spectroscopy and microanalysis.

ORCID

e: elena.taran@unimelb.edu.au

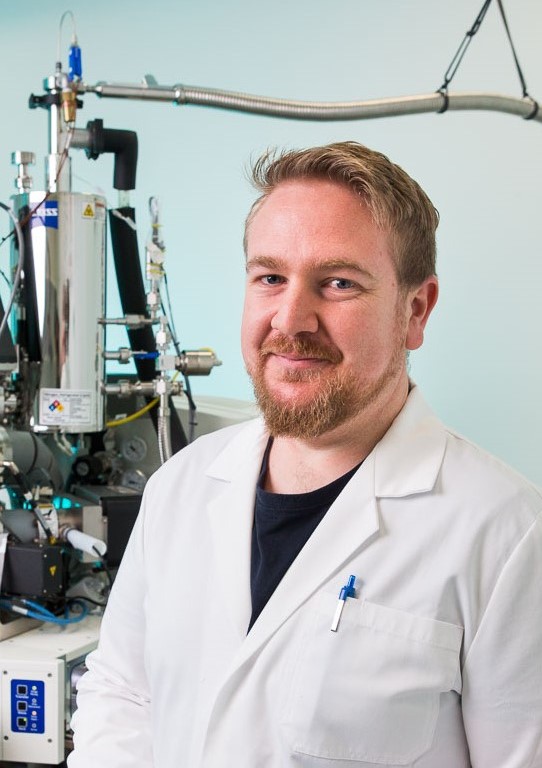

DR ANDERS BARLOW

Academic Specialist - Electron and Ion Microscopy

Anders' background is in materials characterisation and surface chemical analysis. After his PhD he spent 4 years in the UK at a national XPS service laboratory, during which time he was introduced to the helium ion microscope. In 2016 he returned to Australia and joined La Trobe University continuing to apply his experience in surface analysis until in 2018 he joined the MCFP as the HIM specialist. Anders supports researchers in the application of helium ion microscopy to novel challenges in micro and nanoscale imaging of soft materials.

ORCID

e: anders.barlow@unimelb.edu.au

t: 03 903 59639 (x59639)

DAN SMITH

Platform Support Officer - Nanofabrication

Dan previously worked at Hewlett Packard and he has over 25 years of experience in micro/nanofabrication, MEMS and semiconductor manufacturing, process development, integration and characterisation. Dan is based at the Melbourne Centre for Nanofabrication (MCN) where he assists University of Melbourne researchers in accessing and using the facilities at MCN. He provides project support including experimental design, equipment training, process development and characterisation.

e: dan.smith@nanomelbourne.com

t: 03 9902 4377

PAUL BRANNON

Platform Support Officer - Advanced Fluorescence Imaging

Paul has previously worked at the University of Chicago and in the Biological Imaging Facility at Northwestern University. He has a background in molecular biology and optical microscopy, with a focus on confocal microscopy. Paul is responsible for the Advanced Fluorescence Imaging node of the MFCP. He has experience in imaging a wide range of samples, including live cells and nanoparticles.

e: paul.brannon@unimelb.edu.au

t: 03 903 57749 (x57749)

DR DARRYL JOHNSON

Academic Specialist - Cytometry

Darryl has previously worked within the University of Melbourne and the ACR Centre of Excellence for Advanced Molecular Imaging. He has a background in molecular biology, biochemistry and immunology. He is an expert in cell cytometry, confocal microscopy, multiparameter imaging and image analysis.

e: darrylj@unimelb.edu.au

t: 03 903 57749 (x57749)

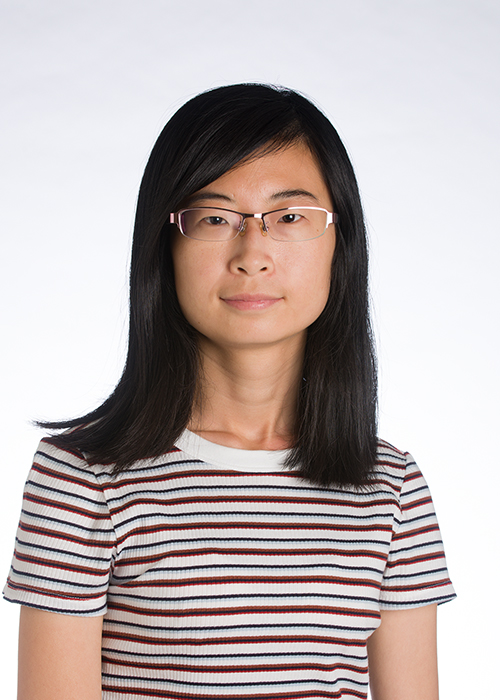

DR TIAN ZHENG

Academic Specialist - Nanomaterials Characterisation

Tian has a background in atomic force microscopy (AFM) and nanomaterial characterisation. In 2017, she joined University of Melbourne as the platform support officer for the Nanomaterial Characterisation Node in MCFP. She has experience in AFM sample preparation, morphological imaging, mechanical characterisation and a range of functional imaging modes for both nanomaterials and biological samples.

e: tian.zheng@unimelb.edu.au

t: 03 903 58587 (x58587)

RAVEEN WIJESURIYA

Platform Support Officer - X-ray Characterisation

Raveen has previously worked in the chemical industry and specialises in the formulation and manufacture of industrial coatings with applications in building, general industrial and food packaging. He also has a background in analytical chemistry including x-ray characterisation and separation science.

e: raveen.wijesuriya@unimelb.edu.au

PROF RAY DAGASTINE

Platform Academic Champion

Ray Dagastine is a Professor in the Department of Chemical Engineering and the Academic leader of the Materials Characterisation and Fabrication Platform. Ray has held successful fellowships as an ARC Future Fellow (2009 – 2013) and Senior Technology Fellow at the Melbourne Centre for Nanofabrication (MCN) (2009-2015). He has established a successful research program in colloid and interfacial science working on both fundamental studies and applied projects in food, personal care products, and minerals processing often around formulation problems. Ray has extensive expertise in atomic force microscopy, optical scattering methods and particle and surface characterisation techniques. He also has research interests in structure in complex fluids, non-equilibrium surface forces, nanomechanical properties of soft materials and diffusion of anisotropic nanoparticles in confinement.

e: rrd@unimelb.edu.au

t: 03 834 44704 (x44704)

PROF GEORGE FRANKS

George Franks is a Professor in the Department of Chemical Engineering and has over two decades of research experience in the ceramics and minerals processing fields. His research interests include suspension rheology, advanced ceramics powder processing, mineral processing, particularly flocculation and flotation, colloid and surface chemistry, alumina surfaces, oxide crystal growth and materials modelling. He is a member of the Particulate Fluids Processing Centre, Melbourne Materials Institute and the Defence Materials Technology Centre.

e: gvfranks@unimelb.edu.au

t: 03 834 49020 (x49020)

All instrumentation on the MCFP platform is available for University of Melbourne researchers, external universities, institutes and research organisations as well as industry partners.

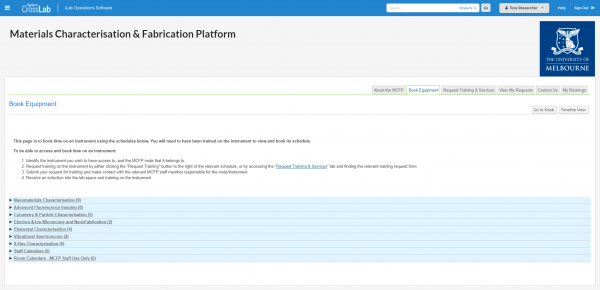

MCFP Booking System

- Request training on MCFP instruments

- Create bookings on MCFP instruments

- Submit samples for analysis

- Submit service/consultation requests

New MCFP users

For University of Melbourne researchers:

Please view the video here for a walkthrough of the iLab registration process. You can also find more information, useful guides, and videos, on the Research Gateway (requires SSO).

If your supervisor cannot be found in the list, they may need to have a new lab group created. Please use the Support Request on the Research Gateway page to ask for help.

For External Academic researchers:

Please register for an iLab account by clicking on the following link, hovering over the Register link in the top right-hand corner, then clicking Register for an iLab Account.

You can find support information including user guides at the Research page.

For Industry researchers:

Please visit our dedicated Services for Industry page here.

For All MCFP Users:

Please take a look at the MCFP Access and Usage Handbook for more information on the platform.

Remember that it is a requirement that all outputs arising from the use of MCFP facilities must acknowledge the platform. Please use the following in the acknowledgement section of any papers:

“This work was performed in part at the Materials Characterisation and Fabrication Platform (MCFP) at the University of Melbourne and the Victorian Node of the Australian National Fabrication Facility (ANFF)”

The MCFP logo should be included on the acknowledgement slide of all presentations that have used MCFP equipment. You can download the MCFP logo for presentations here.

You can use our simple web-form to notify us of new publications:

MCN users

University of Melbourne researchers receive a 30% discount on the Melbourne Centre for Nanofabrication (MCN) instrument rates when accessing the facility through the MCFP's pre-paid block account. UoM researchers can also take advantage of the MCFP's platform support officer, Dan Smith, who is based at MCN. Dan can help you with access, training, process development and technical support. Dan's time is free for all UoM researchers.

How to find us

We are located on the main University of Melbourne campus in Parkville, near to multiple public transport links, see the map above.

Arriving by train into Melbourne Central station you can catch any tram North along Swanston Street and get off at either Lincoln Square for the HIM node, or Stop 1 for all other MCFP nodes.

Otherwise it is only a short (~10-15 minute) walk through Melbourne's bustling streets to reach the campus. There is some on-street parking available surrounding the campus although this is generally very limited.

Below you will find the latest News and Event listings for the MCFP.

You can also follow MCFP on LinkedIn and YouTube to keep up to date with

everything that is happening around the platform.

Visit us on LinkedIn Visit us on YouTube

Upcoming events

Recent News and MCFP Newsletters

Past events

-

Atomic Force Microscopy Workshop 2024

WORKSHOP

WORKSHOP -

MCFP 2022 Workshop: Sample Preparation for Electron and Ion Microscopy

WORKSHOP

WORKSHOP -

MCFP 2022 Webinar Series: X-ray Characterisation at the MCFP

SEMINAR

SEMINAR -

MCFP 2022 Webinar Series: Advanced sample capabilities on the inVia with the Linkam stage

SEMINAR

SEMINAR -

MCFP 2022 Webinar Series: Advanced fluorescence imaging with Zeiss Elyra

SEMINAR

SEMINAR -

MCFP 2022 Webinar Series: Beyond topography – Electrical imaging capabilities on AFM

SEMINAR

SEMINAR -

RACI PhysChem Webinar: Imaging Soft Materials with Light Ion Beams

SEMINAR

SEMINAR

MCFP offers consultation and fee-for-service solutions to industry researchers. We can apply our broad capability and expertise to help answer your process related questions.

To discuss your analysis needs with our Specialists, please either submit an access request online, or email us directly, by following the links below.

Submit a Request Online Contact Us by Email

Materials characterisation

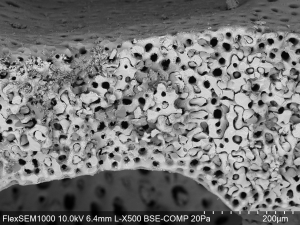

Scanning electron microscopy (SEM) enables the inspection of devices, components, materials, and surfaces. Our flexible SEM capability is applicable to the imaging of metals, ceramics, minerals, semiconductors, polymers, fibres, and particles. We can provide the inspection and measurement of component dimensions, the imaging of surface topography, microanalysis composition by SEM-EDX with an elemental range from boron (5) to californium (98), and the identification of unknown solids, defects, contaminants, and corrosion of solids. We can accept specimens up to 50 mm diameter and 40 mm thickness.

Phase identification

Our X-ray characterisation capability enables the analysis of solids and powders, providing semi-quantitative phase analysis of solids and powders by XRD, elemental and oxide composition by XRF, identification of unknown solids, matching of XRD patterns to ICDD-4+ 2021 Database, crystallinity and amorphous content. Ideally specimens should be in the form of a powder with the consistency of flour – dry, and ground to ~50 μm particle size and generally 2 g is required, but this can be as small as 20 mg, depending on the analysis. Specimen preparation as a service is also available. For solid samples the maximum size for standard data collection is 39 mm in diameter, 5 mm thickness and the sample surface must be flat.

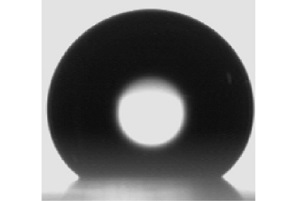

Surface chemistry

Optical imagery of drops placed on a solid surface enables the determination of surface and interfacial parameters. The contact angle of a drop on a surface informs the wetting behaviour of the solid with the liquid. We can provide optical measurements of static and dynamic contact angle, wetting of solid surfaces, surface free energy of solids, and surface and interfacial tension of liquids. Our instrument can accept a maximum specimen size of 220 x 220 (L x W) and 70 mm thickness.

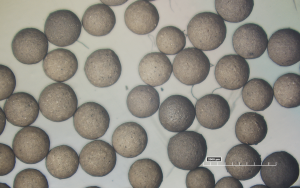

Microscopy and Imaging

We have flexible methods for general purpose imaging of materials including general purpose optical microscopy, the inspection and measurement of component dimensions, the imaging of surface topography, optical 2D/3D microscopy with 3D surface profiles, and high resolution electron microscopy. Please contact us to discuss your needs and we can provide the most suitable imaging technique for your question.

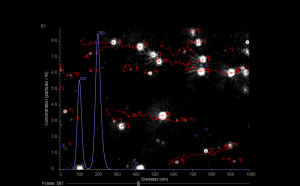

Particle characterisation

Two technologies that can be used to characterize nanoparticles are flow cytometry and nanoparticle tracking analysis. With flow cytometry, a suspension of nanoparticles is passed one-by-one in front of a laser. As they pass through the laser beam they scatter light, and this gives information on particle size and concentration. Nanoparticle tracking analysis also identifies particles with scattered laser light, but uses image analysis to track the movement of individual particles. The size of each particle can then be determined based on the characteristic way they move. We offer the analysis of particle size distribution and concentration for a size range of 10 - 2000 nm and concentration range 106 - 109 particles per mL.