Materials Characterisation and Fabrication Platform

The Materials Characterisation and Fabrication Platform (MCFP) supports materials research through advanced instrumentation, analysis and characterisation. The MCFP is a fee-for-service facility that welcomes all users across the scientific community, from universities and research institutes to industry.

-

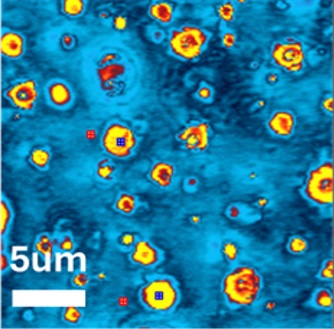

Nanomaterials Characterisation

Nano- and micro-scale characterisation of bulk and thin materials, nanoparticles, living cells and tissues

-

Cytometry and Particle Characterisation

Analysis of cells in suspension

-

Advanced Fluorescence Imaging

Cutting-edge imaging technology of living or fixed samples

-

Electron and Ion Microscopy

High resolution surface imaging and nanoscale milling and patterning

-

X-Ray Characterisation

Investigate the crystalline nature of materials

-

Vibrational Spectroscopy

Confocal Raman and FTIR microspectroscopies

-

Nanofabrication

The MCFP Nanofabrication platform supports University of Melbourne (UoM) researchers accessing the Melbourne Centre for Nanofabrication (MCN) located in Clayton

-

Services for Industry

Meet the Team

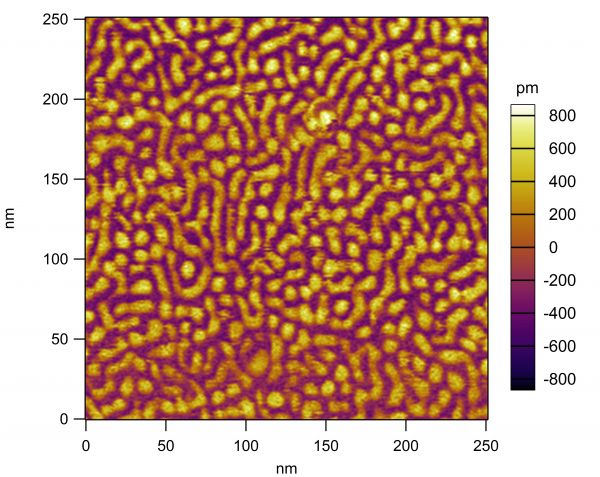

Elena Taran

Platform Manager

Elena is an accomplished leader with a wealth of experience in navigating the complexities of research infrastructure and fostering collaborative, innovative environments. Elena is an Atomic Force Microscopy (AFM) specialist, leveraging this powerful technique to enable and advance research in nanotechnology and materials science.

Anders Barlow

Academic Specialist - Electron and Ion Microscopy

Anders leads the Electron and Ion Microscopy and Vibrational Spectroscopy nodes of the MCFP. He is a materials and surface analysis specialist who can help you with all manner of identification and characterisation of hard and soft materials.

Paul Brannon

Platform Support Officer - Advanced Fluorescence Imaging

Paul leads the Advanced Fluorescence Imaging node of the MCFP and can assist with super-resolution imaging of a wide range samples, including tissues, live cells, and nanoparticles.

Darryl Johnson

Academic Specialist - Cytometry

Darryl leads the Cytometry node of the MCFP with expertise in mass and flow cytometry, and confocal microscopy. He has a background in molecular biology, biochemistry and immunology, and can help you with experimental design, preparation, acquisition, and interpretation.

Dan Smith

Senior Nanofabrication Engineer

Dan leads the nanofabrication capability for the MCFP. Situated in the heart of ANFF-Vic at the Melbourne Centre for Nanofabrication (MCN), Dan has expertise across the most extensive fabrication capability in Melbourne, and can help you from design to device realisation.

Raveen Wijesuriya

Platform Support Officer - X-ray Characterisation

Raveen leads the X-ray Characterisation node of the MCFP, including X-ray diffraction (XRD) and fluorescence (XRF) and all sample preparation required including milling and pellet forming. He will guide you from start to finish of XRD analysis.

Tian Zheng

Academic Specialist - Nanomaterials Characterisation

Tian leads the nanomaterials characterisation (NMC) node of the MCFP. She can provide insight into all modes of modern atomic force microscopy measurements on a range of samples from nanomaterials to biological structures.

Ray Dagastine

Platform Academic Champion

Ray Dagastine is a Professor in the Department of Chemical Engineering and Academic Champion of the Materials Characterisation and Fabrication Platform.

George Franks

Professor

George Franks is a Professor in the Department of Chemical Engineering and has over two decades of research experience in the ceramics and minerals processing fields.

Steering Committee

Prof. Raymond Dagastine (Chair) | Dept. Chemical Engineering | FEIT |

Dept. Chemical Engineering | FEIT | |

Dept. Infrastructure Engineering | FEIT | |

School of Physics | Science | |

Melbourne Dental School | MDHS | |

School of Historical and Philosophical Studies | Arts | |

School of Physics | Science | |

Dept. Chemical Engineering, FEIT | |

Dept. Electrical and Electronic Engineering | FEIT | |

Platform Manager | MCFP |

Advisory Group

Prof. Ann Roberts (Chair) | School of Physics | Science |

Dept. Chemical Engineering | FEIT | |

| School of Chemistry | Science | |

| School of Anatomy and Physiology | MDHS | |

| Dept. Chemical Engineering | FEIT | |

| Dept. Biomedical Engineering | FEIT | |

| Dept. Biomedical Engineering | FEIT | |

| CSL | |

| Dept. Chemical Engineering | FEIT | |

| Platform Manager | MCFP |

All instrumentation on the MCFP platform is available for University of Melbourne researchers, external universities, institutes and research organisations as well as industry partners.

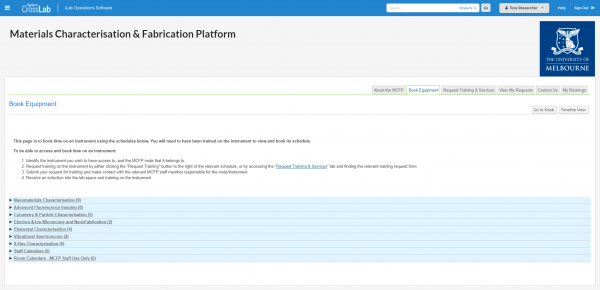

MCFP Booking System

- Request training on MCFP instruments

- Create bookings on MCFP instruments

- Submit samples for analysis

- Submit service/consultation requests

New MCFP users

For University of Melbourne researchers:

Please view the video here for a walkthrough of the iLab registration process. You can also find more information, useful guides, and videos, on the Research Gateway (requires SSO).

If your supervisor cannot be found in the list, they may need to have a new lab group created. Please use the Support Request on the Research Gateway page to ask for help.

For External Academic researchers:

Please register for an iLab account by clicking on the following link, hovering over the Register link in the top right-hand corner, then clicking Register for an iLab Account.

You can find support information including user guides at the Research page.

For Industry researchers:

Please visit our dedicated Services for Industry page here.

MCN Users

University of Melbourne researchers receive a 30% discount on the Melbourne Centre for Nanofabrication (MCN) instrument rates when accessing the facility through the MCFP's pre-paid block account. UoM researchers can also take advantage of the MCFP's platform support officer, Dan Smith, who is based at MCN. Dan can help you with access, training, process development and technical support. Dan's time is free for all UoM researchers.

All MCFP Users

Please take a look at the MCFP Access and Usage Handbook for more information on the platform.

Remember that it is a requirement that all outputs arising from the use of MCFP facilities must acknowledge the platform. Please use the following in the acknowledgement section of any papers:

“This work was performed in part at the Materials Characterisation and Fabrication Platform (MCFP) at the University of Melbourne and the Victorian Node of the Australian National Fabrication Facility (ANFF)”

The MCFP logo should be included on the acknowledgement slide of all presentations that have used MCFP equipment. You can download the MCFP logo for presentations here.

You can use our simple web-form to notify us of new publications:

How to find us

We are located on the main University of Melbourne campus in Parkville, near to multiple public transport links, see the map above.

Arriving by train into Melbourne Central station you can catch any tram North along Swanston Street and get off at either Lincoln Square for the HIM node, or Stop 1 for all other MCFP nodes.

Otherwise it is only a short (~10-15 minute) walk through Melbourne's bustling streets to reach the campus. There is some on-street parking available surrounding the campus although this is generally very limited.

Below you will find the latest News and Event listings for the MCFP. You can also follow MCFP on LinkedIn and YouTube to keep up to date with everything that is happening around the platform.

Recent News and Upcoming Events

Past MCFP events

-

Wednesday 9:30am - 11:30amAdvanced Analytical Tools for the Study of Nanoscale Surface Interactions

Seminar

Seminar -

Friday 10am - 12pmWhat's new in Dynamic Mechanical Analysis (DMA)?

Seminar

Seminar -

Tuesday 1pm - 2:30pmMulti-modal submicron IR (O-PTIR) Spectroscopy and Imaging: Advances in Spatial Resolution, Sensitivity & Multi-modality (IR, Raman & Fluorescence)

Seminar

Seminar -

Atomic Force Microscopy Workshop 2024

WORKSHOP

WORKSHOP -

MCFP 2022 Workshop: Sample Preparation for Electron and Ion Microscopy

WORKSHOP

WORKSHOP -

MCFP 2022 Webinar Series: X-ray Characterisation at the MCFP

SEMINAR

SEMINAR -

MCFP 2022 Webinar Series: Advanced sample capabilities on the inVia with the Linkam stage

SEMINAR

SEMINAR

MCFP offers consultation and fee-for-service solutions to industry researchers. We can apply our broad capability and expertise to help answer your process related questions.

To discuss your analysis needs with our Specialists, please either submit an access request online, or email us directly, by following the links below.

Submit a Request Online Contact Us by Email

Materials characterisation

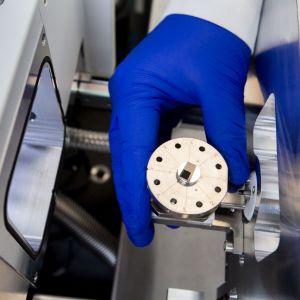

Scanning electron microscopy (SEM) enables the inspection of devices, components, materials, and surfaces. Our flexible SEM capability is applicable to the imaging of metals, ceramics, minerals, semiconductors, polymers, fibres, and particles. We can provide the inspection and measurement of component dimensions, the imaging of surface topography, microanalysis composition by SEM-EDX with an elemental range from boron (5) to californium (98), and the identification of unknown solids, defects, contaminants, and corrosion of solids. We can accept specimens up to 50 mm diameter and 40 mm thickness.

Phase identification

Our X-ray characterisation capability enables the analysis of solids and powders, providing semi-quantitative phase analysis of solids and powders by XRD, elemental and oxide composition by XRF, identification of unknown solids, matching of XRD patterns to ICDD-4+ 2021 Database, crystallinity and amorphous content. Ideally specimens should be in the form of a powder with the consistency of flour – dry, and ground to ~50 μm particle size and generally 2 g is required, but this can be as small as 20 mg, depending on the analysis. Specimen preparation as a service is also available. For solid samples the maximum size for standard data collection is 39 mm in diameter, 5 mm thickness and the sample surface must be flat.

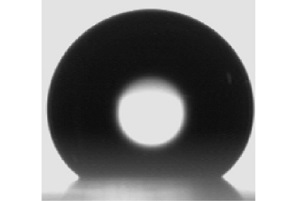

Surface chemistry

Optical imagery of drops placed on a solid surface enables the determination of surface and interfacial parameters. The contact angle of a drop on a surface informs the wetting behaviour of the solid with the liquid. We can provide optical measurements of static and dynamic contact angle, wetting of solid surfaces, surface free energy of solids, and surface and interfacial tension of liquids. Our instrument can accept a maximum specimen size of 220 x 220 (L x W) and 70 mm thickness.

Microscopy and Imaging

We have flexible methods for general purpose imaging of materials including general purpose optical microscopy, the inspection and measurement of component dimensions, the imaging of surface topography, optical 2D/3D microscopy with 3D surface profiles, and high resolution electron microscopy. Please contact us to discuss your needs and we can provide the most suitable imaging technique for your question.

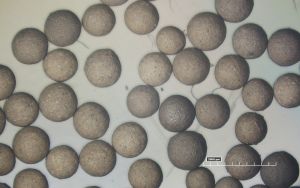

Particle characterisation

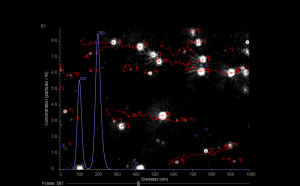

Two technologies that can be used to characterize nanoparticles are flow cytometry and nanoparticle tracking analysis. With flow cytometry, a suspension of nanoparticles is passed one-by-one in front of a laser. As they pass through the laser beam they scatter light, and this gives information on particle size and concentration. Nanoparticle tracking analysis also identifies particles with scattered laser light, but uses image analysis to track the movement of individual particles. The size of each particle can then be determined based on the characteristic way they move. We offer the analysis of particle size distribution and concentration for a size range of 10 - 2000 nm and concentration range 106 - 109 particles per mL.

We are committed to having a positive impact on laboratory practices, making our workflows more environmentally responsible and sustainable

Our Ethos

At the MCFP, we promote and support laboratory practices and research programs aligned with the University of Melbourne's Sustainability Framework and SP2030, and the UN Sustainable Development Goals. The direct operational actions we take now, guided by a Sustainability mindset, will allow us to meet our needs today while ensuring we can meet the needs of the future.

What sustainable actions are we taking?

-

Advocating for turning off equipment when not in use; always switching off monitors at the end of the day; lowering the sashes on fumehoods when not in use; changing the set temperature of ultra-low temp (ULT) freezers from -80oC to -70oC. All strategies save energy and in the case of the ULT can save up to 40%.

-

Worked with administration to have fair trade and/or rainforest alliance tea, coffee, and sugar in the department tearoom; promoting the “Green Caffeen” reusable cups (found at many cafes on campus); initiated discussions about having a food waste bin in the tearoom and a collection point for ice packs in our building that can then be reused by researchers or donated to external businesses via Pack share.

-

Promoting ride to work: Darryl encouraged the team to attend the ride to work event, provided data on the bike infrastructure on campus (repair points, bike cages and hubs, change rooms and showers). As a result, the MCFP team members that worked in Parkville campus in 2023, used in 95% of cases public transport/cycled/walked to commute to work.

How are we supporting sustainability efforts?

-

To mark 10 years of enabling research at the University of Melbourne, the Materials Characterisation and Fabrication Platform (MCFP) created a new initiative, the MCFP Sustainability Research Grants.

The grants were created to provide much needed seed-funding for projects that address critical issues related to environmental conservation, renewable energy, climate change mitigation, sustainable development, etc. You can read more about the 2024 outcomes below.

-

Concrete contributes enormously to the carbon footprint of the building and construction sectors. Our capabilities are enabling researchers to develop more sustainable concretes, through the incorporation of recycled materials, and test their properties against conventional concretes.

-

Our researchers leverage the breadth of the MCFP capabilities to develop and study novel materials for the capture and storage of energy. From light-harvesting nanomaterials, to flexible energy-generation textiles, and ultra-efficient batteries.

-

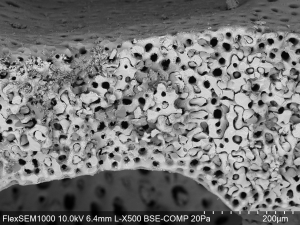

Membrane technologies play a large role in the separation of gases and liquids from one another in waste and other streams. Our researchers use the high resolution and sensitivity of our capabilities to look at the internal structure of these membranes and how nanoscale variation improve their performance.

-

Ensuring food security into the future is of significant importance in our world of ever-growing population density. We are enabling researchers to develop new biofertilisers synthesised by recovering nutrients from human urine in waste streams towards sustainable and circular agriculture.

2024 MCFP Sustainability Grant Outcomes

In 2024 we invested in 9 early- mid-career researchers in the field of sustainability, awarding a total of $12,500 in critical seed-funding. These grants covered cutting-edge research on solar cells and advanced battery technologies to critical studies on the impact of pollution on insects and the Great Barrier Reef.

See the impact in these recent publications

-

mRNA delivery enabled by metal-organic nanoparticles

Y. Gu et al. with Darryl Johnson in Nature Communications

-

Tensile Control of Vibrational Strong Light-Matter Coupling with Flexible Polyester Films

G.E. Akinoglu et al. in Advanced Functional Materials

-

Adaptive Radiative Thermal Management Using Transparent, Flexible Ag Nanowire Networks

G.E. Akinoglu et al. in ACS Applied Materials and Interfaces

Meet our Sustainability Champion

Dr Darryl Johnson is our Sustainability Champion. In addition to managing the Cytometry Node of the MCFP, Darryl works extensively on sustainability initiatives within the team and beyond. He actively incorporates sustainability actions in his everyday work, inspiring others to do the same. Darryl has been part of the Faculty of Engineering and IT green impact team (The Greengineers) since 2022 and became the team lead in 2023.

Due to his remarkable contributions championing sustainability, UoM offered him the opportunity to enrol in the ACTS (Australasian Campuses Towards Sustainability) Carbon Literacy Course, which comes with the prospect of receiving an official Carbon Literate accreditation. Additionally, Darryl has recently completed the laboratory Accredited Professional program to promote sustainability in science run by My Green Lab organisation.

Darryl channels his passion for sustainability into a mission to raise awareness and educate as many individuals as possible in the office and lab spaces. He is now part of the Australian National Fabrication Facility (ANFF) Sustainability Expert Working Group, implementing initiatives at national level.